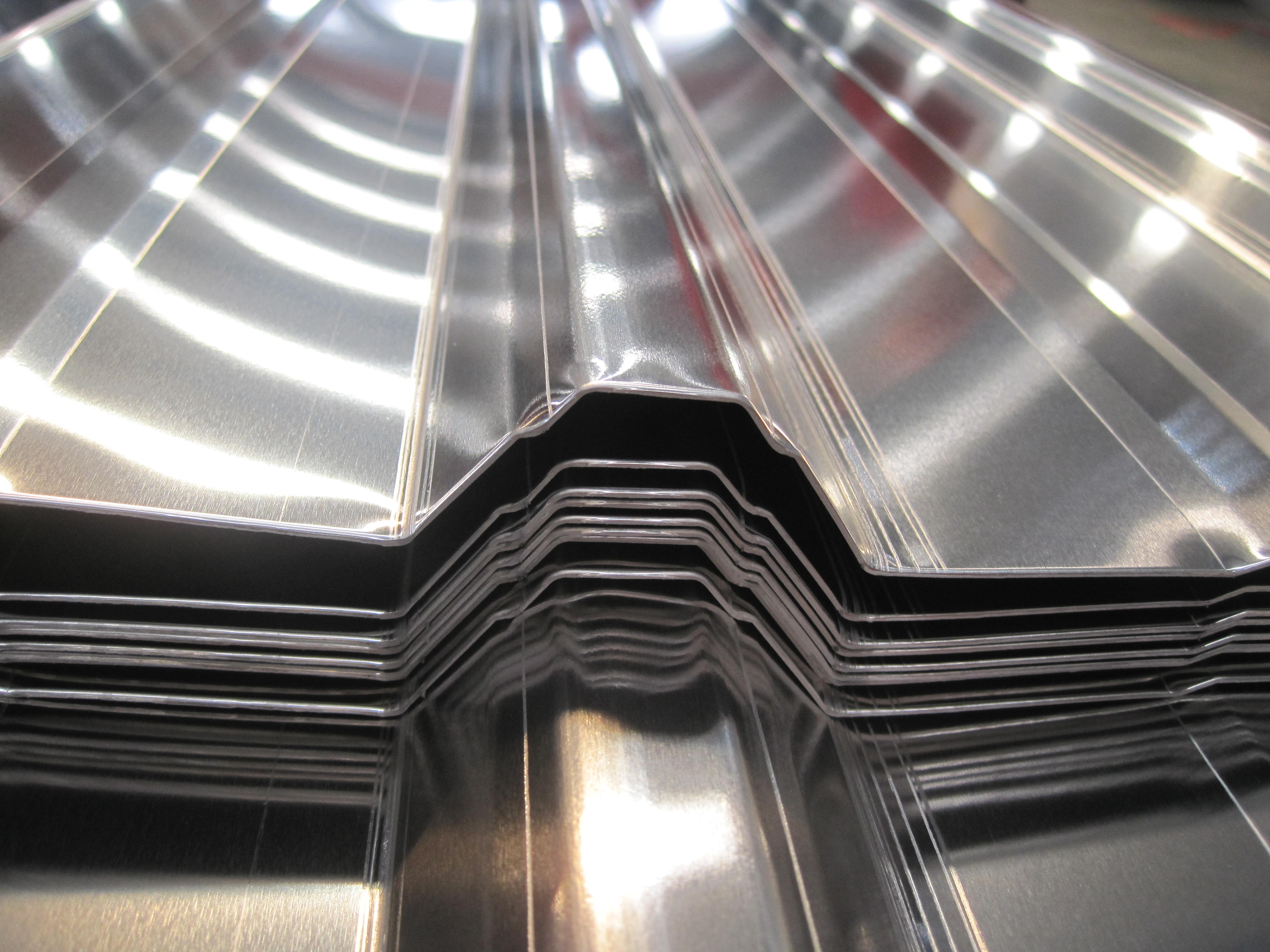

In the aluminum roofing sheet factory or the application process, sometimes there will be the above black spot situation, what is this situation? Let’s look at it. First of all, the aluminum roofing sheet materials, aluminum roofing sheet manufacturers produced by the aluminum roofing sheet cover is 0.5mm thick LF21 aluminum plate processing. This type of aluminum roofing sheet has many parts of the same material, similar shape and same process, but similar shape parts processed at the same time have no such failure. And it’s not the fault of a defective raw material. It’s on the processing technology, cover silver plating process for roughly: outgoing parts machining pretreatment ─ ─ ─ ─ galvanized zinc leaching plating copper electroplating silver ─ ─ painting 823 ─ ─ dip coating into the Treasury.

In the process of aluminum roofing sheet plating, first of all, it is possible that some production link of plating has changed, leading to failure. However, the investigation found that no such failure occurred in similar parts processed at the same time without any change in production conditions. Therefore, the factors of changing electroplating production conditions are excluded. According to the previous production experience, the most common cause of discoloration of silver plating parts is the influence of sulfur element on silver plating layer.

In the past, silver plated parts have not been packaged and sealed in time and stored in the electroplating factory house for a long time. However, the defective parts are timely packaged and stored in dry containers after silver plating. It can be seen that this is not affected by the air atmosphere in the workshop. In the spray painting process, it was found that the top cover of the spray painting processing, the whole batch of rerepair records. The most important reason is that the gap is not plugged, allowing the paint mist to enter and adhere to the surface of the silver plating layer and cannot be removed. In order to prevent this kind of failure, it is recommended to seal the gap with 3M adhesive tape in the process to prevent the paint fog from entering.

Through such elimination method, we found the root of the problem, and we immediately took measures to prevent the recurrence of hidden dangers, so that the surface of aluminum roofing sheet is as bright as new, and the delivery rate is greatly increased