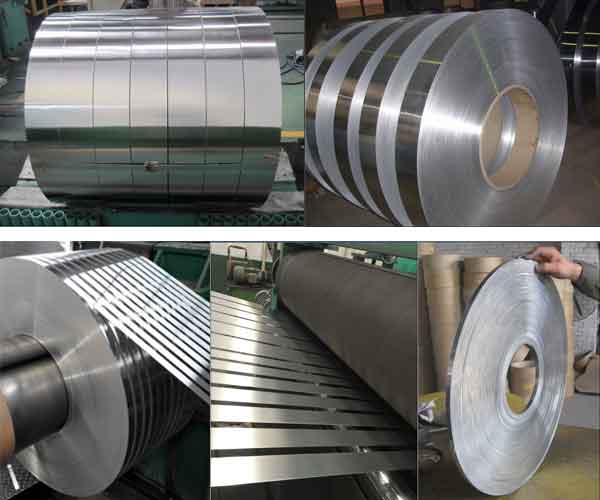

The weight and strength of the aluminum strip can be improved by cold working. The aluminum can be cast by any casting method and can be processed by various machine tools. The corrosion resistance of aluminum alloy can be improved by adopting protective measures. After the longitudinal shear machine components cut into the required width of aluminum strip. Used in the manufacture of aircraft fuel tanks, oil pipes, as well as transportation vehicles, sheet metal parts for ships, hardware products, etc. The raw material of the aluminum strip is a pure aluminum or aluminum alloy cast aluminum coil, hot rolled aluminum coil, which is rolled into a thin aluminum coil of different thickness and width by a cold rolling mill.

The surface pretreatment of the aluminum strip is mainly degreasing and derusting, and the method is the same as the pretreatment of the liquid paint. Apply conductive putty according to defect degree of workpiece and smooth it with sandpaper after drying, you can proceed to the next process. If some parts of the workpiece are not required to be coated, they can be covered with protective glue before preheating to avoid spraying paint. The sprayed workpiece is sent to the oven for heating to solidify the powder. After the coating is cured, the surface is cleaned and the coating of the workpiece is inspected. Any defects should be reworked.